Synthetic Fibres:

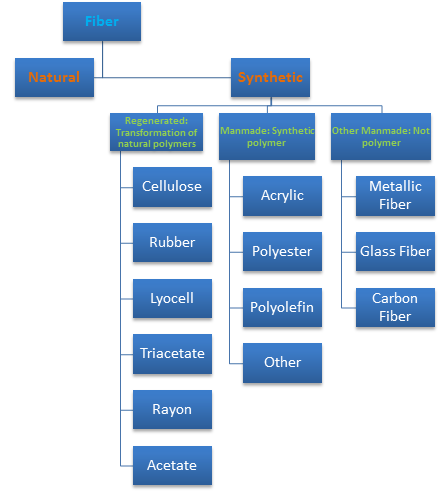

Synthetic fibers are a subset of the larger area of textiles. Textiles can be natural or synthetic. Natural fibers include cotton, fur, wool, etc. Regenerated fibers are natural materials that have been processed into a fiber structure. Regenerated fibers such as cellulose and wood pulp are used to make materials such as rayon and acetate.

Synthetic fibers are man made from chemicals. They are generally based on polymers and are stronger than natural and regenerated fibers.

Synthetic fibres are used for making clothes and many other useful things. They may be entirely synthetic or semisynthetic. Semisynthetic fibres, like rayons, are made by using natural polymers as the starting material. Purely synthetic fibres, on the other hand, are made from chemicals. Polyesters, nylons and acrylics are purely synthetic fibres.

Types of Synthetic Fibres:

Rayons:

These are the most widely used semisynthetic fibres. They are derived from cellulose and are available in three different varieties— viscose, cuprammonium (or cupro) and acetate rayons.

Viscose Rayon:

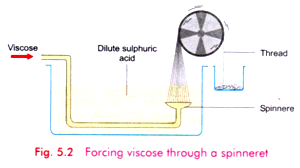

Cellulose (say, cotton) is dissolved in a mixture of sodium hydroxide (NaOH) and carbon disulphide (CS2, a solvent). A viscous liquid (i.e., a liquid which cannot flow freely) called viscose is obtained. The viscose is then forced through spinnerets (which have small holes) into an acid bath, and filaments of viscose rayon are obtained.

Cuprammonium Rayon (or cupro):

A copper sulphate solution (blue), on treatment with an excess of an ammonia solution, gives a deep blue solution of a compound, cuprammonium hydroxide. Cellulose is dissolved in this solution. The resulting solution is forced through spinnerets into an acid bath to give the filaments of cuprammonium rayon.

Acetate rayon:

In this case, cellulose is dissolved in a mixture of acetic acid, sulphuric acid and some other chemicals. The solution is forced through spinnerets to obtain filaments of acetate rayon.

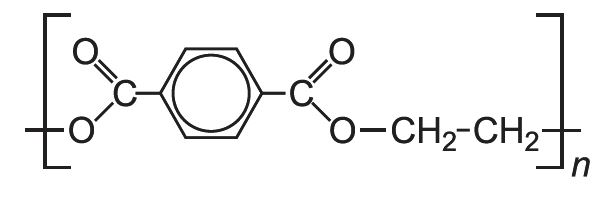

Polyesters:

The first synthetic fibre obtained was of this class. Polymers obtained by the reaction between certain sets of organic (carbon-containing) compounds form a melt which can be spun into filaments. The special property of these filaments is that they can be stretched several times their original length. Terylene and Dacron belong to this class of synthetic fibres. Terylene is used to make clothes. In general, polyesters are used to make textiles, bottles and insulating tapes.

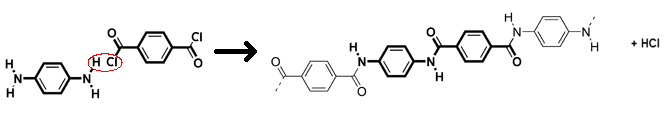

Polyamides (nylons):

Nylon 6 and nylon 6, 6 are the most important fibres of this class. Nylon 6 is made of an organic compound which contains six carbon atoms. Nylon 6, 6 is made of a more complicated monomer. Nylon was first made in 1935.

It was intended to be a substitute for silk and was used in place of silk in parachutes in 1941, when the USA entered World War II. Nylon is very suitable for women’s wear. Having a high tensile strength, nylon is also used for making ropes.

Acrylics:

Acrylic fibres are a substitute for natural wool. These polymers decompose without melting. So, they are dissolved in a suitable solvent and the solution is forced through spinnerets to obtain filaments. The filaments can be cut into staples and the staples spun into yarns.

Acrylic fibres are crimpy (i.e., wavy) and not straight like polyester or nylon fibres. So acrylic yarns appear to be bulky and compete with wool. They are generally used to make knitwear, upholstery and artificial furs.

Acrylic fibres are not easily acted upon by moisture, chemicals or bacteria.