Biodegradable Polymers:

‘‘Biodegradable’’ means ‘‘capable of undergoing decomposition into carbon dioxide, methane, water, inorganic compounds, and biomass’’.

Every polymer is degradable. They degrade in mass, strength and molecular weight with time. Most of the polymers that we already knew, have a period of 100-1000 years to degrade in fully. The specialties in biodegradable polymers are, they degrade quickly when comparing to non- biodegradable polymers and their byproducts are eco-friendly (biocompatible) such as CO2, water, methane, and inorganic compounds or biomass that is easily scavenged by microorganisms.

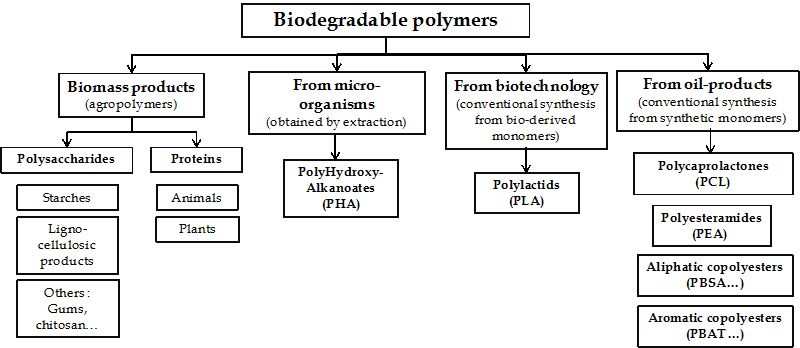

Types of Biodegradable Polymers:

Biodegradable polymers can be categorized under two main topics according to their formation method.

- Agro polymers

biomass products

- Bio-polyesters

polymers obtained by microbial productions

conventional synthesis from bio-derived monomers

from oil-products

1.Agro-Polymers:

Main agro-polymers presented in this chapter are the polysaccharides and the proteins. They are often used to elaborate multiphase materials.

1.1.Polysaccharides:

Polysaccharides are the most abundant macromolecules in the biosphere. These complex carbohydrates constituted of glycosidic bonds are often one of the main structural elements of plants and animals exoskeleton (cellulose, carrageenan, chitin…). The polysaccharides presented in this chapter are starch, chitin, chitosan, and pectins, successively.

1.1.(a).Starch:

Starch is mainly extracted from cereals (wheat, corn, rice…) and from tubers (potatoes, manioc…). It is stocked in seeds or roots and represents the main plant energy reserve.

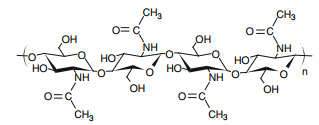

1.1.(b).Chitin and Chitosan:

Chitin is the second most abundant agro-polymer produced in nature after cellulose. It appears in nature as ordered crystalline microfibrils forming structural components in the exoskeleton of arthropods or in the cell walls of fungi and yeasts. It is an acetylated polysaccharide composed of N-acetyl-D-glucosamine groups linked by ![]() . From chitin, chitosan is obtained by deacetylation.

. From chitin, chitosan is obtained by deacetylation.

1.1.(c).Pectin:

Pectin is a linear macromolecule constituted of ![]() D-galacturonic acid. This monomer unit could be partially replaced by

D-galacturonic acid. This monomer unit could be partially replaced by ![]() L-rhamnose leading to a new structure named rhamnogalacturonan I. A third pectin structural type is rhamnogalacturonan II, which is a less frequent, but complex and highly branched polysaccharide.

L-rhamnose leading to a new structure named rhamnogalacturonan I. A third pectin structural type is rhamnogalacturonan II, which is a less frequent, but complex and highly branched polysaccharide.

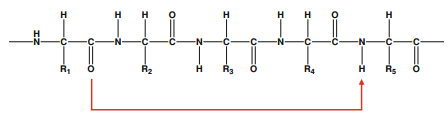

1.2.Proteins:

Proteins are agro-polymers. They are an important renewable resources produced by animals, plants, and bacteria. The term ‘‘protein’’ comes from the Greek, proteios, for ‘‘primary, first and foremost’’. A certain number of proteins have received much attention as biodegradable polymers but few have led to actual industrial scale-up due to the high production cost and the low product performance.

In terms of potential sources, soy protein, corn protein (zein…) and wheat proteins (gluten…) are among the main plant proteins. Casein, collagen protein or gelatin, and keratin are important animal proteins. Lactate dehydrogenase, chymotrypsin, and fumarase constitute the main bacterial proteins.

2.Biodegradable Polyesters:

We distinguish biobased (PLA, PHA…) and non-renewable polyesters (PCL, PBSA, PBAT…) in the following.

2.1.Polyesters Based on Agro-Resources:

Some biobased polyesters are now largely available like PLA and PHAs, with different industrial productions.

2.1.(a).Poly(Lactic Acid):

Lactic acid is a chiral molecule existing as two stereoisomers, L- and D-lactic acid which can be produced by different ways, i.e., biologically or chemically synthesized.

2.1.(b).Polyhydroxyalkanoates:

PHAs are a family of intracellular biopolymers synthesized by many bacteria as intracellular carbon and energy storage granules. PHAs are mainly produced from renewable resources by fermentation. A wide variety of prokaryotic organisms, accumulate PHA from 30 to 80 % of their cellular dry weight.

2.2.Petroleum-Based Polyesters:

A large number of biodegradable polyesters are based on petroleum resources, obtained chemically from synthetic monomers. According to the chemical structures, we can distinguish polycaprolactone, aliphatic copolyesters, and aromatic copolyesters. All these polyesters are soft at room temperature.

2.2.(a).Polycaprolactone:

It is usually obtained by ROP of e-caprolactone in the presence of metal alkoxides (aluminium isopropoxide, tin octoate…). PCL is widely used as a PVC solid plasticizer or for polyurethane applications, as polyols. But, it finds also some applications based on its biodegradable character in domains such as biomedicine (e.g. drugs controlled release) and environment (e.g. soft compostable packaging).

2.2.(b).Aliphatic Copolyesters:

A large number of aliphatic copolyesters based on petroleum resources are biodegradable copolymers. They are obtained by the combination of diols such as 1,2-ethanediol, 1,3-propanediol or 1,4-butadenediol, and of dicarboxylic acids like adipic, sebacic or succinic acid.

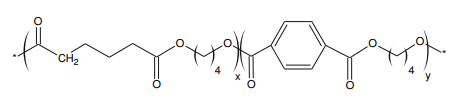

2.2.(c).Aromatic Copolyesters:

Compared to totally aliphatic copolyesters, aromatic copolyesters are often based on terephthalic acid. For instance, Fig. below gives the chemical structure of poly(butylene adipate-co-terephthalate) (PBAT).

also find the relevant notes