INTRODUCTION:

The oscilloscope is the equipment to see the changing signal voltage directly. Basically, it suits to observe the periodically repeated signal. It is difficult to see the signal with the irregular period or occurs the only once. There is equipment which has the memory to observe the signal which occurs the only once, too.

Here, I introduce the basic operation principle of the oscilloscope (or synchroscope).

Screen display principle of the oscilloscope:

The oscilloscope shows the time with the horizontal axis (the X-axis) and shows the voltage with the vertical axis (the Y axis).As for the screen, the CRT (Cathode-Ray Tube) is often used. It displays in the principle which is the same as the TV. That is, it displays the signal wave form with the deflection of the electron beam (it moves to upper and lower either side).

Y AXIS – Vertical – Voltage V:

There is at least one input channel for the Voltage signal V to be shown, about the two channels (or dual trace) we will speak later. This signal passes through an adjustable gain amplifier and the selection knob sets the amplitude value for each Y division. So setting 2 V/Div means that the maximum watching amplitude of the input signal is 16V (2V multiplied by 8 vertical divisions) or referring to centre (zero) is 8V positive and 8V negative.

X AXIS – Horizontal – TIME BASE:

This axis too has a selection knob to set the temporal base or how long is a division. For example setting 10ms/Div means that to trace the whole X axis it spends 0.1 seconds (10 ms multiplied by 10 divisions = 100 ms). We will call scan everyone of this sweeps.

WORKING PRINCIPLE:

An electronic beam light up a dot on the screen. Where the dot depends on the two deflection systems, horizontal and vertical. The vertical axis is driven by the input signal while the horizontal one by the internal time base. Without input signal, the dot moves from left to right tracking a flatten horizontal line.

Now suppose to apply at the vertical input a 10Vpp (peak to peak) triangular wave signal with 25Hz of repetition frequency. That means 25 cycles per second so a period is:

1/25 = 0,04 seconds = 40ms.

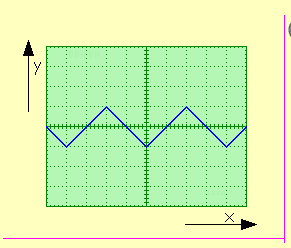

Setting the gain to 5V/Div and the time base to 10ms/Div what is traced at every scan on the time axis appears as depicts this picture:

There is shown a 2 divisions height signal repeated every 4 divisions on X axis.

Now if I switch the gain, consequently changes the vertically filled divisions (Y axis). Switching instead the time base, changes of course the occupied horizontal divisions (X axis). So we realise that every signal with any frequency, voltage and shape can be shown graphically by the oscilloscope just setting it up properly. Within of course max and min limits reported on selectors.

TRIGGER:

It is necessary to emphasise that every scan on the X axis draws a new trace and the time base knob defines the trace’s length of time, 0.1 seconds in our example. At this point we have to understand when a scan begins, or best, what starts it. The trigger perform just that function. We call trigger the event that starts each single scan.

This fundamental section allows two settings:

- Selecting the edge between positive and negative.

- Presenting the trigger voltage level in continuous range (through analog potentiometer), not by predefined steps.

Practically the above settings define that the trigger event (beginning of scan) happens when the input signal crosses the trigger level in one of the two possible ways, rising for the positive edge and falling for the negative one.

The example trace in previous picture starts at zero voltage level (centre of Y axis) hence the trigger level was preset around zero Volt while the selected edge was negative. At the end of scan (end tracing on X axis) the electronic beam is turned off and brought back to the left of the screen (starting point). Then it waits a new trigger event.

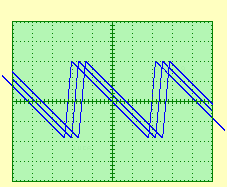

With this system happens that, for constantly repeated waves, an identical trigger event restarts a new scan that retrace exactly the previous shape. In that condition the input signal is triggered (locked or coupled or hooked up) so we can see a stable waveform on the grid. Without trigger instead the input signal is shifting on the X axis.

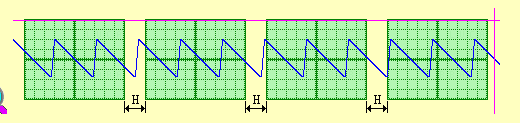

Let us make clearer this concept with a picture. Supposing to have a continuous saw tooth wave thescope meterr shows just the fraction fitted in one scan. The beam at end of scan switches off and go back to the left. This operation spends a fixed time known as “HOLD-OFF” time (H). If now begins a new scan, the new starting point is different from the previous one, please see this picture:

Here is therefore what is shown without trigger,

our input signal running sliding on temporal axis.

Trigger Modes in Oscilloscope:

All oscilloscopes have at least 3 basic trigger modes:

- SINGLE – In this one-shot mode, the scan starts only once at first trigger event. After that, it must be manually re-enabled by a push-button to wait for another start event. So in single-mode a trace is drawn just once at first trigger event and the lenght of time scan depends on time base preset.

- NORMAL – A scan restarts only on trigger event. At the end of scan the beam go to the starting point (left of screen) to wait for next event. Hence in normal mode, when trigger events lack there is not any trace.

- AUTO – Automatic, the scan restarts automatically at each end of scan also without trigger event, so a trace is always shown without input signal too. When the input signal is small, such to not generate a trigger event, it is however shown even if sliding as above described.

Moreover, on some oscilloscopes, there is a special trigger section. It may allows a delay from trigger event rather then widen the time base into a scan part. Since that section is specific and change model by model it must be seen case by case. Here let us remain on basic use.