What is a Lathe Machine?

Working Principle: The lathe is a tool that holds the piece between two rigid and strong centers or in a chuck or face plate. The cutting tool is held and rigidly held in a tool post that feeds rotary work. Normal cutting operations are performed with the cutting tool fed in parallel or at right angles to the working axis.

The cutting tool may also be fed at an angle relative to the axis of work for machining tapers and angles.

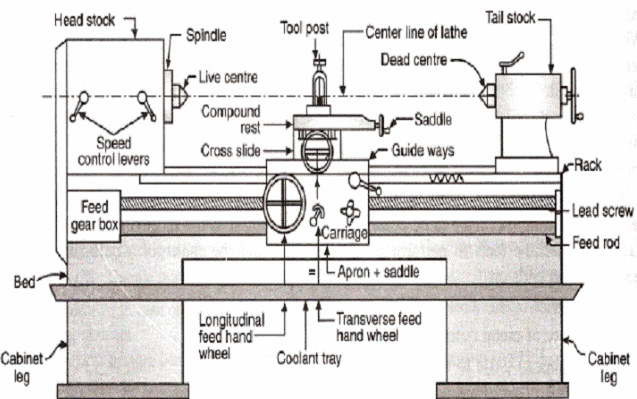

Construction: The main parts of the lathe are the bed, headstock, quick changing gear box, carriage and tailstock.

Lathe Components

- Bed: The bed is a heavy and sturdy casting on which the working parts of the lathe are mounted. It carries the headstock and tail stock for supporting the work piece and provides a base for the movement of carriage assembly which carries the tool.

- Legs: The legs carry the entire load of machine and are firmly secured to floor by foundation

- Headstock: The headstock is clamped on the left hand side of the bed and it serves as housing for the driving pulleys, back gears, headstock spindle, live centre and the feed reverse gear. The headstock spindle is a hollow cylindrical shaft that provides a drive from the motor to work holding devices.

- Gear Box: The quick-change gear-box is placed below the headstock and contains a number of different sized

- Carriage: The carriage is located between the headstock and tailstock and serves the purpose of supporting, guiding and feeding the tool against the job during

- Tailstock: The tailstock is a movable casting located opposite the headstock on the ways of the bed. The tailstock can slide along the bed to accommodate different lengths of workpiece between the centers. A tailstock clamp is provided to lock the tailstock at any desired position. The tailstock spindle has an internal taper to hold the dead centre and the tapered shank tools such as reamers and drills.