Operations Performed on a Lathe Machine

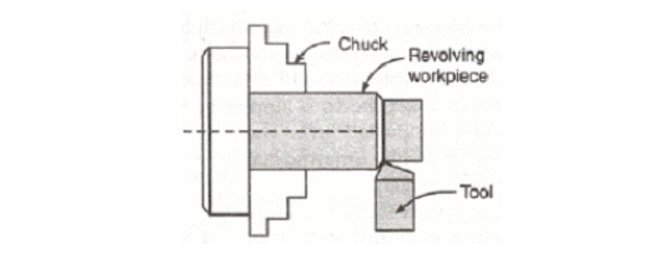

- Plain Turning: Plain turning is the operation of removing excess amount of material from the surface of a cylindrical job.

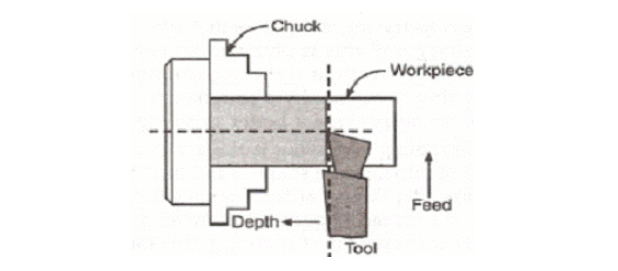

- Facing: The facing is a machining operation by which the end surface of the work piece is made flat by removing metal from it.

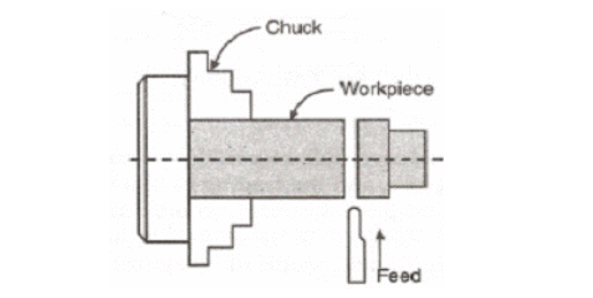

- Parting: The parting or cutting off is the operation of cutting away a desired length of the work piece, i.e., dividing the work piece in two or more parts.

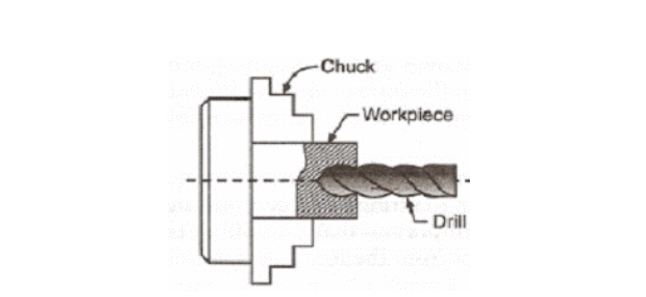

- Drilling: Drilling is the operation of producing a cylindrical hole in the work piece.

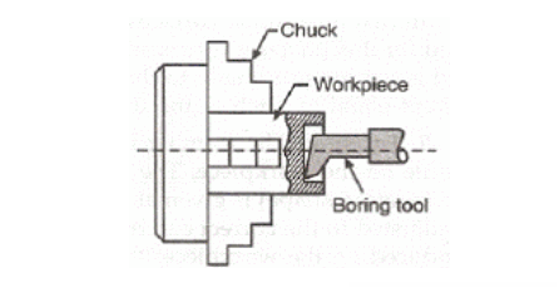

- Boring: The boring operation is the process of enlarging a hole already produced by drill.

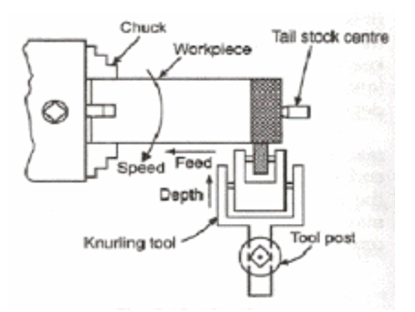

- Knurling: The knurling is a process of embossing (impressing) a diamond-shaped or straight-line pattern into the surface of work piece. Knurling is essentially a roughening of the surface and is done to provide a better gripping surface.

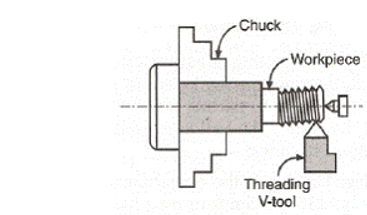

- Threading: Threading is the act of cutting of the required form of threads on the internal or external cylindrical surfaces.

- Chamfering: Chamfering removes the burrs and sharp edges, and thus makes the handling safe. Chamfering can be done by a form tool having angle equal to chamfer which is generally kept at 45°.