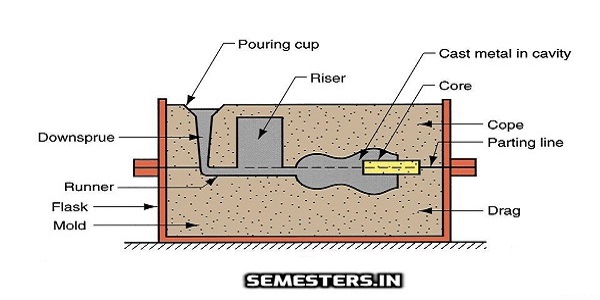

Important Casting Terms, Definitions and Terminology:

In order to learn about the casting process, it is important for us to get familiarized with important casting terms definitions, and terminology. These are some of the important terms which will be commonly used throughout the process of manufacturing.

1. Flask:

A metal or wood frame, without a fixed top or bottom, in which the mold is formed. Depending upon the position of the flask in the molding structure, it is referred to by various names such as drag- lower molding flask, cope- upper molding flask, and cheek- intermediate molding flask used in three-piece molding.

2. Pattern:

It is the replica of the final object to be made. The mold cavity is made with the help of a pattern.

3. Parting line:

This is the dividing line between the two molding flasks that make up the mold.

4. Molding sand:

Sand, which binds strongly without losing its permeability to air or gases. It is a mixture of silica sand, clay, and moisture in appropriate proportions.

5. Facing sand:

The small amount of carbonaceous material sprinkled on the inner surface of the mold cavity to give a better surface finish to the castings

6. Core:

A separate part of the mold, made of sand and generally baked, which is used to create openings and various shaped cavities in the castings.

7. Pouring basin:

A small funnel-shaped cavity at the top of the mold into which the molten metal is poured.

8. Sprue:

The passage through which the molten metal, from the pouring basin, reaches the mold cavity. In many cases, it controls the flow of metal into the mold.

9. Runner:

The channel through which the molten metal is carried from the sprue to the gate.

10. Gate:

A channel through which the molten metal enters the mold cavity.

11. Chaplets:

Chaplets are used to support the cores inside the mold cavity to take care of their own weight and overcome the metallostatic force.

12. Riser:

A column of molten metal placed in the mold to feed the castings as it shrinks and solidifies.

13. Vent:

Small opening in the mold to facilitate the escape of air and gases.