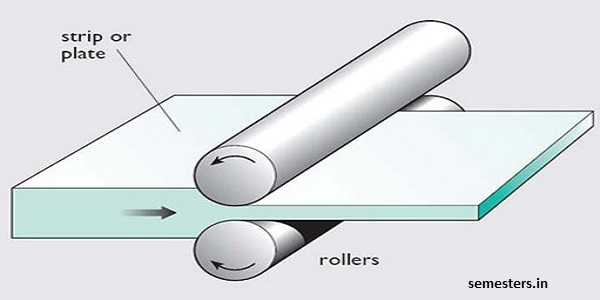

What is Rolling Process?

Rolling is the most commonly used deformation process. It consists in the passing of metal between two rollers, which exert compressive stresses, reducing the thickness of the metal. Where simple shapes need to be made in large quantities, rolling is the cheapest process. Rolled products include sheets, structural shapes, and rails, as well as intermediate shapes for drawing or forging. The circular shapes, the “I” beams, and the railways are made with grooved rollers.

Types of rolling operations

- In metalworking, rolling is a metal forming process where metal material is passed through a pair of rollers. Rolling is classified according to the temperature of the laminated metal.If the metal temperature is above its recrystallization temperature, the process is called hot rolling.

- If the temperature of the metal is below its re-crystallization temperature, the process is called cold rolling.

- In terms of usage, hot rolling processes more tonnage than any other manufacturing process, and the cold rolling process the most tonnage out of all cold working processes.

- There are many types of rolling processes, including

- flat rolling,

- foil rolling,

- ring rolling,

- roll bending,

- roll forming,

- profile rolling, and

- controlled rolling.